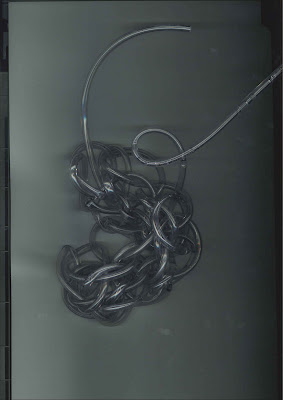

Here is a test we did today with the pump going through four panels of knitting

Tuesday, October 5, 2010

Testing with knitted panels and pump

We are now under way knitting our 4000m of tubing - we are making 48 1x1m knitted panels.

We now have a tank and pump set up too so we have tested 4 panels of knitted tubing.

Rockit have also sponsored us with 4x1000Watt lights to light up our project which can be seen in the following images. http://www.rockit.co.nz

We now have a tank and pump set up too so we have tested 4 panels of knitted tubing.

Rockit have also sponsored us with 4x1000Watt lights to light up our project which can be seen in the following images. http://www.rockit.co.nz

Thursday, September 30, 2010

Scaffolding up, tubes arrived and knitting started

We now have all 113 rolls of tubing from Dynex which makes up 3990m in length. Each roll is 30m and has an internal diameter of 5.5mm.

We are using 40mm dowling to knit with. We are making panels that are 1m x 2m.

Our scaffolding has also gone up for us to start testing out our project. It is 2m x 2m x 6m.

Now we just have to test out the knitted panels with Water Dynamics and then start knitting.

We are using 40mm dowling to knit with. We are making panels that are 1m x 2m.

Our scaffolding has also gone up for us to start testing out our project. It is 2m x 2m x 6m.

|

| 6m high scaffold and rolls of tubing |

|

| Knitting the tubing |

Now we just have to test out the knitted panels with Water Dynamics and then start knitting.

Materials and sponsorship

Thank you to all of our generous sponsors, without their help this project wouldn't be possible.

Water Dynamics who are helping us with everything to do with pumping water through our installation. Such as a pump, an air injector system, a tank and all of the connections. http://www.waterdynamics.co.nz/

Access Scaffolding who have provided us with the structure our project will be supported by. They have given us a 2x2x6m scaffold system to use. http://www.scaffolding.co.nz/

Dynex Extrusions Ltd who gave us a huge discount on our 4000m of tubing which has a 5.5mm internal diameter. http://www.dynex.co.nz/

Hi-Q Electronics Ltd who gave us 1000 cable ties to connect our knitted panels. http://www.hiq.co.nz/

3M who gave us tape to use. http://www.3m.com/

Water Dynamics who are helping us with everything to do with pumping water through our installation. Such as a pump, an air injector system, a tank and all of the connections. http://www.waterdynamics.co.nz/

Access Scaffolding who have provided us with the structure our project will be supported by. They have given us a 2x2x6m scaffold system to use. http://www.scaffolding.co.nz/

Dynex Extrusions Ltd who gave us a huge discount on our 4000m of tubing which has a 5.5mm internal diameter. http://www.dynex.co.nz/

Hi-Q Electronics Ltd who gave us 1000 cable ties to connect our knitted panels. http://www.hiq.co.nz/

3M who gave us tape to use. http://www.3m.com/

Thursday, September 2, 2010

Knitting on a larger scale

Today I have tested out 40m of 5mm vinyl tubing in order to find out wether this tube is suitable on a larger scale.

The tube worked out quite well on this scale. 40m of tubing covered an area of 800mm x 400mm

= 320 000mm²

Ideally what we want is one side to be 8m x ~1m which is an area of 8000000mm²

Knitting 40m of tubing took approximately 40 minutes therefore about 1 minute per metre of tubing

If we have 4 sides each 8m x 1m then according to these calculations we will need 4000m of tubing

If we have 3 sides each 8m x 1m then according to these calculations we will need 3000m of tubing

|

| 40m before |

|

| 40m after |

The tube worked out quite well on this scale. 40m of tubing covered an area of 800mm x 400mm

= 320 000mm²

Ideally what we want is one side to be 8m x ~1m which is an area of 8000000mm²

Knitting 40m of tubing took approximately 40 minutes therefore about 1 minute per metre of tubing

If we have 4 sides each 8m x 1m then according to these calculations we will need 4000m of tubing

If we have 3 sides each 8m x 1m then according to these calculations we will need 3000m of tubing

Tuesday, August 31, 2010

New tube, new work

Monday, August 30, 2010

Current proposal

Our proposal seeks an atmosphere of unpredictability and spontaneity.

We are working with the idea of Re-Casting an everyday material, which in our case is clear tubing. This material is a household object which tends to be hidden, but through exposing this material and turning it into a complex structure both the function and aesthetics of the material are emphasised. The knitted tubing forms a flexible yet strong structure – the material is able to be pulled and compressed but it will still retain its form. This process transforms the rigidity of the material into a flexible structure. The application of the simple process of knitting and layering on a large scale creates a complex system which is amplified by water being pumped through it.

We are retaining the intended function of the tubing by using it as a means for the transportation of a fluid. But it is made more complex by the water travelling through the knitted pattern. The bubbles trace the path of the tubes. Throughout the entire structure the tubes are connected to the difference sides of the structure so that for one side there is only one path for the water to take and when viewing this installation the water will make its way to the base from the top over the course of the night. The rate of flow of water is dependent on the movement and concentration of people around and inside the structure, and the pump will be triggered by movement of people, controlled via motion detecting sensors placed around the structure.

Initially, the audience is oblivious to their individual effects on the skyrise, as familiarity grows they become aware of the influence they exert and this process reveals to them the control they have over the appearance of the structure and an interactive connection is established. As the water moves through, the light from inside will be refracted creating an impulsive and ever-changing image. The reflective qualities of the tubing and the water will work with the lights to give the structure a weightless and serene aesthetic. This will mask the internal support elements of the knitted walls. Four steel poles are holding the entire structure together and the knitted tubing will provide further strength giving a self supporting appearance to our proposal.

From inside there will be a sensory experience for the audience. As the water moves through ad around the person standing inside the structure, they are fully enveloped by the movement and a rain like atmosphere spontaneously awakened by their unaware interactions with the design is made apparent. They will be able to hear the movement of water whilst viewing the map like image the bubbles and water create by their presence. The vibrations due to the flow of water, combined with the plastic and textured surface of the knitted arrangement will provide a highly interactive experience.

We are still looking for the right tubing - the tubing we have been using currently becomes creased/crushed and blocks any water from travelling through. We need something flexible enough to knit with but strong enough to keep it's shape.

We are working with the idea of Re-Casting an everyday material, which in our case is clear tubing. This material is a household object which tends to be hidden, but through exposing this material and turning it into a complex structure both the function and aesthetics of the material are emphasised. The knitted tubing forms a flexible yet strong structure – the material is able to be pulled and compressed but it will still retain its form. This process transforms the rigidity of the material into a flexible structure. The application of the simple process of knitting and layering on a large scale creates a complex system which is amplified by water being pumped through it.

We are retaining the intended function of the tubing by using it as a means for the transportation of a fluid. But it is made more complex by the water travelling through the knitted pattern. The bubbles trace the path of the tubes. Throughout the entire structure the tubes are connected to the difference sides of the structure so that for one side there is only one path for the water to take and when viewing this installation the water will make its way to the base from the top over the course of the night. The rate of flow of water is dependent on the movement and concentration of people around and inside the structure, and the pump will be triggered by movement of people, controlled via motion detecting sensors placed around the structure.

Initially, the audience is oblivious to their individual effects on the skyrise, as familiarity grows they become aware of the influence they exert and this process reveals to them the control they have over the appearance of the structure and an interactive connection is established. As the water moves through, the light from inside will be refracted creating an impulsive and ever-changing image. The reflective qualities of the tubing and the water will work with the lights to give the structure a weightless and serene aesthetic. This will mask the internal support elements of the knitted walls. Four steel poles are holding the entire structure together and the knitted tubing will provide further strength giving a self supporting appearance to our proposal.

From inside there will be a sensory experience for the audience. As the water moves through ad around the person standing inside the structure, they are fully enveloped by the movement and a rain like atmosphere spontaneously awakened by their unaware interactions with the design is made apparent. They will be able to hear the movement of water whilst viewing the map like image the bubbles and water create by their presence. The vibrations due to the flow of water, combined with the plastic and textured surface of the knitted arrangement will provide a highly interactive experience.

|

| Working process |

|

| Plan, section, detail & perspective |

We are still looking for the right tubing - the tubing we have been using currently becomes creased/crushed and blocks any water from travelling through. We need something flexible enough to knit with but strong enough to keep it's shape.

More drawings and images

Work for our first presentation to jury

|

| Perspective - Holly |

|

| Section - Holly |

|

| Plan & Axonometric - Holly |

|

| Axonometric - Holly |

|

| Pump attatched to knitted tube |

|

| Knitted tubes at 1:1 and knitted electrical cable at 1:20 |

|

| 1:20 representational model made from electrical cable |

|

| Perspective - Steven |

|

| Perspective - Steven |

Thursday, August 26, 2010

Site visit

The site for the competition was open to be visited.

Site: Shed 1 & Shed 2, 135 Halsey Street, Auckland

View Larger Map

Site: Shed 1 & Shed 2, 135 Halsey Street, Auckland

View Larger Map

|

| Panorama of site |

|

| Panorama of site |

|

| Panorama of site |

Monday, August 23, 2010

Water pumping through clear tubing

Videos here show how the water moves through the clear tubing. Bubbles and water can be seen clearly tracing the knitted pattern.

Video showing water being pumped through a knitted tube with varying pressures.

Video showing what happens when colour (red watercolour) is added

Through research we have found examples of others doing similar projects:

Fluid Sculpture by Casual Profanity

Bit.Flow by Julius Popp

Video showing water being pumped through a knitted tube with varying pressures.

Video showing what happens when colour (red watercolour) is added

Through research we have found examples of others doing similar projects:

Fluid Sculpture by Casual Profanity

Bit.Flow by Julius Popp

Friday, August 20, 2010

Knitting with clear PVC tubing

Clear tubes are flexible and hold no shape but through knitting, like the electrical cable, it becomes strong and can provide structural strength.

Here is some of the knitting we have done with the PVC tubing:

From this experimentation, it has become apparent that the "knit stitch" rather than the method based on "finger knitting" is better and easier to do.

Next we will try pumping water through the knitted tubes to see what kind of effect that gives to the project. We hope it will amplify the pattern of the tubes, showing traces and mapping out paths.

Here is some of the knitting we have done with the PVC tubing:

|

| All knitted using the "knit stitch" method |

|

| Made using crochet |

|

| Knitting method based on finger knitting |

From this experimentation, it has become apparent that the "knit stitch" rather than the method based on "finger knitting" is better and easier to do.

Next we will try pumping water through the knitted tubes to see what kind of effect that gives to the project. We hope it will amplify the pattern of the tubes, showing traces and mapping out paths.

Concept drawings

Subscribe to:

Posts (Atom)